English

Views: 0 Author: Site Editor Publish Time: 2021-07-14 Origin: Site

There are many communication methods currently used for smart lighting, and the main wired technology are DALI (digital addressable lighting interface), PLC, RS485, Ethernet (IEEE 802.3), EIB /KNX, LonWorks, DMX512 and C-Bus, etc; wireless technologies mainly include ZigBee, Bluetooth, WiFi, Infrared, ordinary RF and Z-wave. These agreements have their own advantages in their respective fields and occupy their respective advantageous markets. Among them, the DALI control bus adopts a master-slave structure. The master control device sends out control commands for adjusting the lights, and the bus transmits the control commands. The independent control device as a slave device or the built-in control device placed in the lamp accepts and executes the commands. At the same time, when the master control device issues a query command, the slave device passes the bus sends its own status information to the master control device. The master control device issues a re-operation command based on the status information of the slave device. One interface of the DALI control bus can connect up to 64 addressable control devices/equipment and up to 16 addressable groups. Multiple interfaces can be interconnected through the network in order to control a large number of interfaces and lamps. In this way, functions such as scene combination, dimming control, and fault feedback can be realized.

In order to solve the problem that the control devices of different manufacturers are compatible with the DALI standard but not compatible with each other, DALI-2 is upgraded on the basis of the original version of DALI (or DALI-1). DALI-2 is the second major version of the DALI protocol standard IEC 62386, or DALI Version 2. In terms of certification, DALI-2 logo adopts compulsory certification. Products with DALI-2 logo must be tested and approved by DiiA accredited laboratories. This is crucial to the development and growth of standards. DiiA adopts an independent DALI-2 certification program. Products that have passed DALI-2 certification will independently verify the test results. Compared with the current DALI products on the market whose reliability is entirely based on self-declaration, DALI-2 has more significant interchangeability, supervision and more functions.

The standards for the certification of DALI-1 control devices are: IEC 62386-101: 2009 "Digital Addressable Lighting Interface Part 101: General Requirements-System", IEC 62386-102: 2009 "Digital Addressable Lighting Interface Part 102" : General Requirements-Control Devices", IEC 62386-207: 2009 "Digital Addressable Lighting Interface Part 207: Special Requirements for Control Devices LED Module (Equipment Type 6)".

The standard for DALI-2 control device certification is IEC 62386-101: 2018 "Digital Addressable Lighting Interface Part 101: General Requirements-System", IEC 62386-102: 2018 "Digital Addressable Lighting Interface Part 102" : General Requirements-Control Devices", IEC 62386-207: 2018 "Digital Addressable Lighting Interface Part 207: Special Requirements for Control Devices LED Module (Equipment Type 6)".

The equipment used in DALI-1, DALI-2 control device detection: ProbitLab test device, ProbitLab2 test device, as shown in Fig. 1. The supporting equipment also includes AC and DC power supply PCR6000LE, power analyzer WT3000, Tektronix digital phosphor oscilloscope DPO7054C (bandwidth is 500 MHz, sampling rate is 5GS/s), illuminance meter B520, current probe TCP0030A, silicon detector DET10A/M.

Fig. 1 ProbitLab test device and ProbitLab2 test device

The ProbitLab test device can only test the control devices that do not integrate bus power in DALI-1 and DALI-2.

The ProbitLab2 test device can not only test all types of control devices in DALI-1 and DALI-2 (including control devices with integrated bus power), it can also detect control devices such as

bus power, application controllers, key devices, absolute input devices, presence detection sensors, and light sensors in the DALI system.

There are a total of 103 procedural clauses for the complete inspection of DALI-1 control device, while DALI-2 has 144 procedural clauses. Below, we select 6 procedural clauses that frequently cause problems in testing for comparative analysis.

Pre-test

As the most important item in the DALI-2 test, "Pre-Test" requires 7 parameters:

1) Whether the sample is powered by the bus power supply;

2) Whether the sample is integrated with bus power; 3) Start-up time (can only be declared on the manual);

4) Equipment type (declared on the nameplate or manual);

5) Discharge time (can only be declared on the manual);

6) Whether it is suitable for DC power supply (declared on the nameplate or manual);

7) The manufacturer needs to declare whether the control device sample tested this time is a new factory. If it is a new factory, the program will jump to "FactoryDefault102" for testing. If it is not a new factory, run "QUERY OPERATING MODE" for inspection."

Overvoltage protection

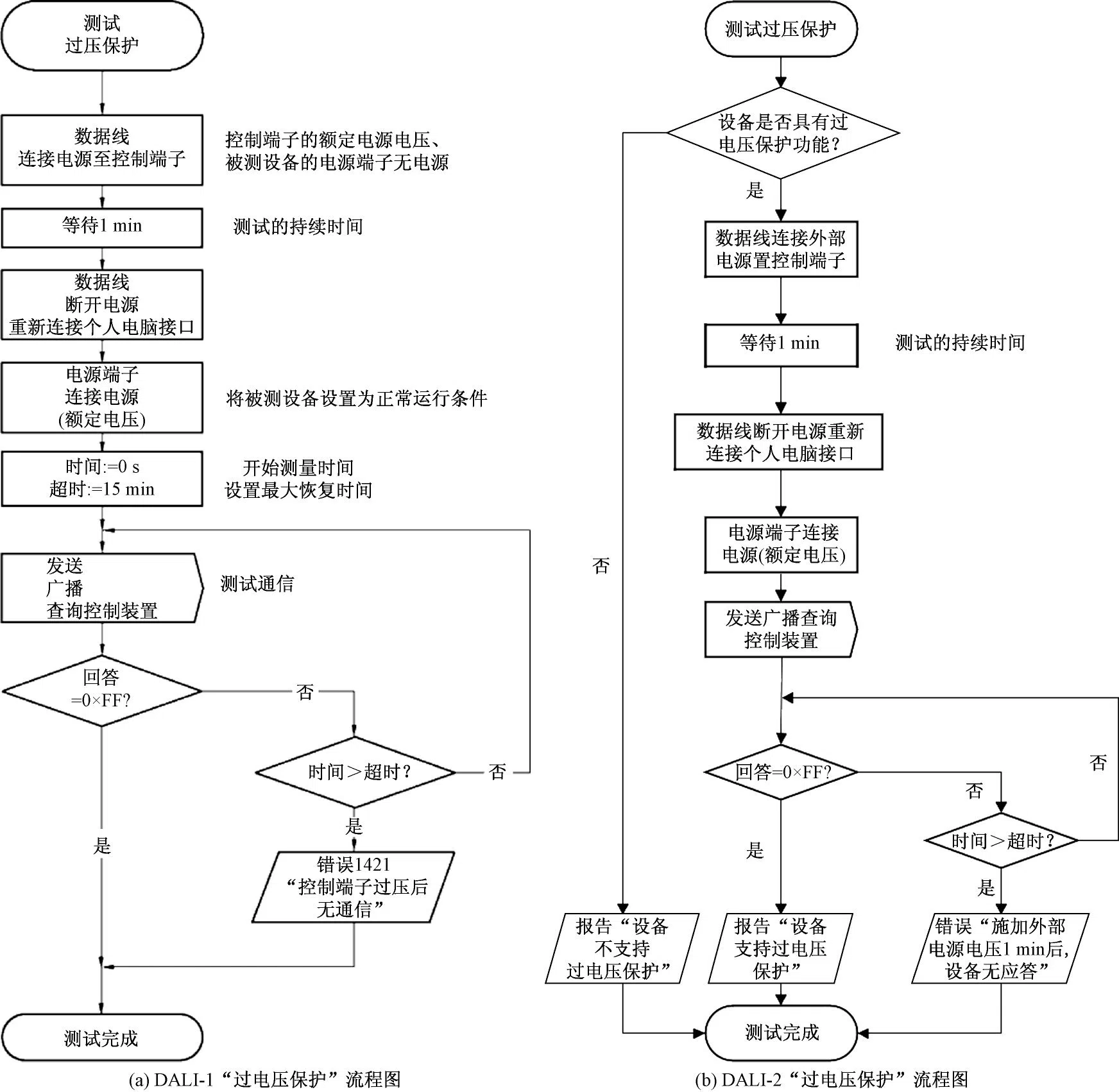

This clause is mainly used to detect whether the LED control device has the "over-voltage protection" function. The program flow of the comparison between DALI-1 and DALI-2 is shown in Fig. 2. "Overvoltage protection" is mainly used to prevent the control device from being connected to the DALI port by mistake when the L and N lines are connected to the DALI port, which may cause overvoltage damage to the control device. In the program clause, it is necessary to connect the external power supply voltage for 1 min to the DALI port, then remove the external power supply voltage, and connect the control device to the DALI bus to still work normally (this external power supply voltage needs to be carried out according to the different areas of use of the DALI equipment Choose, for example, 220 V ~ 50 Hz in China).

"Overvoltage protection" is optional in DALI-2 detection. In the actual inspection process, it was found that many manufacturers have cancelled the "overvoltage protection" function in order to save costs. However, considering the durability of the control device and the compatibility of the system, it is recommended to retain the "overvoltage protection" function. In the DALI-1 test, this item is called the "overvoltage protection" test procedure, and it is also an optional item.

In the DALI-1 test, the control device has a waiting time of 15 minutes after the external power supply voltage is removed, while DALI-2 requires the control device to resume work immediately after the external power supply voltage is removed. It can be seen that the DALI-2 detection is more stringent than the DALI-1 detection, and it has higher requirements for the overvoltage protection performance of the data terminal of the control device.

Fig. 2 Contrast flow chart of DALI-1 and DALI-2 overvoltage protection

This clause is mainly used to detect the current level of the LED control device. The program flow of the comparison between DALI-1 and DALI-2 is shown in Fig 2. The DALI bus requires that the current at the DALI end of the control device cannot exceed 2 mA during the entire program operation.

DALI-1 only detects the current effective value when the voltage of the DALI port of the control device is 22.5V, while DALI-2 detects 4 voltage states from 0V to 22.5V. It can be seen that the "current level" performance of the control device that meets the DALI-2 detection standard in the DALI system is stronger than that of the control device that meets the DALI-1 detection standard.

The sender voltage program clause is mainly used to detect: whether the LED control device can respond to different voltages and current levels; whether the high and low voltage ranges are within the range specified by the DALI bus.

Transmitter rising and falling edge

The sender voltage program clause is mainly used to detect the accuracy of the rise and fall times of the first and last levels in the backward frame of the LED control device sender.

The "Sending Terminal Bit Timing" program item mainly detects the pulse width time of 1 or 2 half-bit high and low levels of the DALI bus data terminal backward frame, so as to strictly define the DALI bus data terminal backward frame 1 or 2 half-bit high and low pulse width time The pulse width time range of the level enhances the compatibility of DALI-2 standard control devices in different DALI systems.

Through the above analysis of the 6 program clauses detected by the DALI control device, it can be seen that DALI-2 has made considerable progress over DALI-1, which is more conducive to the interconnection of products. The promotion of DALI-2 certification can promote the communication protocol of the smart control system to become more standardized and unified. A unified communication protocol can save personnel training costs. Modular use and maintenance reduce labor and time costs, and its universal The modular structure makes the product design more flexible, faster, and cheaper.