English

Views: 0 Author: Site Editor Publish Time: 2020-12-24 Origin: Site

UV light curing technology is a new technology for green industry. It was once rated as an industrial technology with "5E" characteristics by the North American Radiation Curing Committee, which fully demonstrated the characteristics of this technology.

The so-called 5E, namely Efficient, is highly efficient. UV curing can achieve complete curing in a few seconds, and the production efficiency is higher; Energysaving, energy saving, UV products are fast curing at room temperature, and the energy consumption is generally only 1/10 to 1 of thermal curing /5;Environmentalfriendly, environmentally friendly, UV curing materials do not contain or only a small amount of solvents, and the energy used for UV curing is electricity, no fuel or gas, no CO2 generation, so UV curing is known as "green technology"; Economy, economical, compact UV curing device, assembly line production, fast processing speed, thus saving space, high labor productivity, UV curing process ensures thinner film, and has excellent performance to reduce raw material consumption, which is conducive to reducing economic costs; Enabling, wide adaptability, the UV product can be adapted to a variety of substrates, such as paper, wood, plastic, metal, leather, stone, glass, ceramics and almost all hard and soft materials.

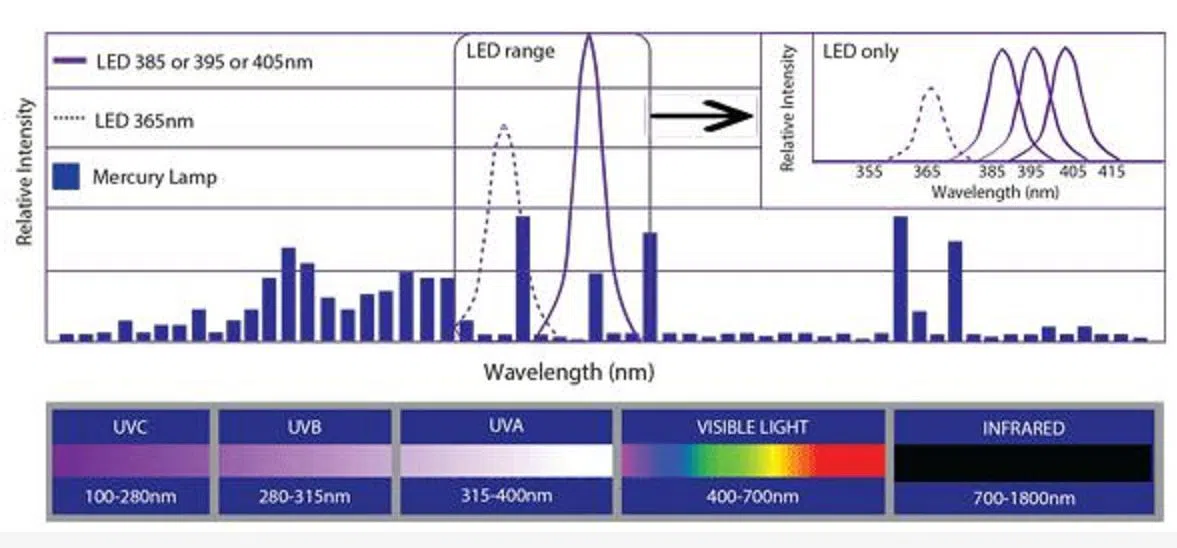

Even though UV light curing technology has so many advantages, there are some unavoidable shortcomings. UV mercury lamps have a limited service life; UV mercury lamps have a large energy consumption, but the effective use of energy is not high, and only the input energy About 20% of the energy produces ultraviolet rays, while 20% is visible energy, and 40% is heat. From the spectrum of Figure 4, we can also see that in addition to the commonly used 300-400nm band for effective curing, there are In many other wavebands, the infrared rays emitted will increase the temperature of the substrate, which can also explain the reason why traditional UV mercury lamps are not suitable for heat-sensitive materials; although UV mercury lamps are relatively solvent-based In terms of ink, because there is no VOC emission, it is environmentally friendly and environmentally friendly. However, UV mercury lamps also have some hidden pollution. For example, due to the high pressure, high temperature and strong radiation of mercury lamps, it is easy to cause the surrounding oxygen molecules to occur. Chemical reactions produce ozone, and ozone not only has an adverse effect on the atmosphere, but also has a greater impact on health.

Compared with ordinary UV mercury lamps, the advantages of LED-UV are:

·Cold light source, no thermal radiation, low temperature rise on the surface of the illuminated object, solve the long-term thermal damage problem in optical communication and liquid crystal production, especially suitable for liquid crystal edge banding, film printing and other occasions requiring small temperature rise. The heat generation is small, which can solve the problem of high heat generation of mercury lamp printing equipment and unbearable staff. In addition, the LED-UV light source emits high-purity single-band ultraviolet light with almost no infrared output. It is a cold light source, and the processed parts will not be deformed by heat.

·High efficiency: The light energy of LED-UV is highly concentrated in a certain ultraviolet spectrum with effective curing effect. The actual use effect is comparable to the curing effect of traditional high-pressure mercury lamp UV light source with light intensity of 1000~2000mW/cm2. Shorten the curing time. The UV light of the traditional mercury lamp looks very bright, but the heat is very high, because its spectrum is very wide, the UV spectrum that is really effective for curing only accounts for part of the energy, and a considerable part of it is in the visible light range (miscellaneous Light) and infrared spectrum (resulting in heat generation), serious damage to the eyes of the operator and easy to thermally deform the processed workpiece.

·Long life: The service life of LED-UV lamps is more than 10 times that of traditional mercury lamps, and the service life is not affected by the number of switches.

· Momentary switch, no need to warm up to reach the maximum power UV output, can be restarted instantly after turning off.

·High energy, stable light output, good uniform irradiation effect, and improved production efficiency.

·The effective irradiation area can be customized, the length is from 20mm to 1000mm.

·It does not contain mercury and does not produce ozone. It is a safer and more environmentally friendly alternative to traditional light source technology.

·Low energy consumption, the power consumption is only 10% of the traditional mercury lamp curing machine, which can save 90% of the power.

·Maintenance cost is almost zero, and the use of UV-LED curing equipment saves at least 10,000 yuan/set of consumables every year.